Products

Contact

Tel +86-519-86212328

Tel: +86-519-86217191

Fax: +86-519-86211771

Email: hlroll@163.com

Address: No. 28, Xinshan Road, Caoqiao Industrial Park, Wujin District, Changzhou

Ceramic Printing Roller

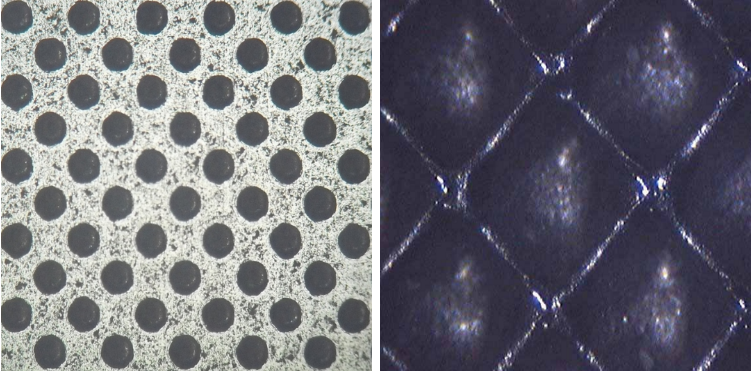

High-precision wear-resistant ceramic anilox rollers are widely used in carton ink printing machines, various flexographic printing machines in the packaging and printing industry, anodized aluminum, gold and silver cards, various composite films, optical films, protective films, lithium battery separators and Precision coating machines in the carbon belt industry. ● The high-precision quality of the polka dot roller is suitable for higher-speed and high-efficiency operation of the equipment. ● The ceramic coating that is denser, more delicate and strong and wear-resistant than the traditional process ensures that it is processed into a smooth and smooth surface to meet the engraving high-line mesh type. ● Thinner mesh wall and optimal opening and depth ratio, so that more volume per unit area can be obtained. ● Smooth mesh inner wall makes the anilox roller have excellent

Category

Keywords: ceramic roller/metal roller/coated roller uniform roller

Description

High Precision Wear Resistant Ceramic Anilox Roller

Widely used in carton ink printing machines, various flexographic printing machines in the packaging and printing industry, anodized aluminum, gold and silver cards, various composite films, optical films, protective films, lithium battery separators and precision coating machines in the ribbon industry Wait.

● The high-precision quality of the roller is suitable for higher-speed and high-efficiency operation of the equipment.

● The ceramic coating that is denser, more delicate and strong and wear-resistant than the traditional process ensures that it is processed into a smooth and smooth surface, which meets the engraving high-line mesh type.

● Thinner mesh walls and optimal opening and depth ratios allow for more volume per unit area.

● The smooth inner wall of the mesh makes the anilox roller have excellent release and transfer performance, and obtain more and more uniform transfer layers.

● Accurate mesh accuracy and uniform mesh volume to achieve accurate and controllable transfer of ink or coating fluid.

● The choice of a variety of network types can meet the needs of different transfer volumes under different conditions.

Product Specifications

Effective engraving diameter of roll surface: Φ50~ 600mm

Effective engraving length of roll surface: L100~ 5800mm

Number of engraving lines: 50~ 2000 L/in (20~ 800 L/cm)

Network type

Mesh shape: hexagonal, square pits and **, twill and other specific design mesh types

Mesh arrangement angle: 60 °, 45 °, 30 ° and other specific requirements, twill 1~ 89 °

Quality accuracy

圆跳动:0.005~0.01 mm

圆柱度:0.01 mm

动平衡品质级别:G2.5

Excellent wear-resistant ceramic coating properties

● Anti-corrosion bottom nickel-chromium coating

● Special pure chromium oxide (Cr2O3) surface

● Special ceramic sealing agent for re-protection

● Porosity: 1~ 3% (can engrave 2000 L/in mesh)

● Coating hardness: HV0.3 ≥ 1250

● Bonding strength: 40 - 60Mpa

Selection of reticulate volume

The choice of suitable anilox volume is based on the different properties of the equipment (uniform scraping method, working accuracy and running speed, etc.), the characteristics of the ink or coating liquid, the printing materials with different ink absorption or coating liquid properties and the different ink or coating quantities required for the graphic form on the flexographic printing plate. Refer to the "Anilox Roller Mesh Geometry Parameters and Volume Table" to select the appropriate anilox specifications. The corresponding mesh types of different shapes and transfer quantities can be designed and customized according to special needs.

Related Products

Feedback